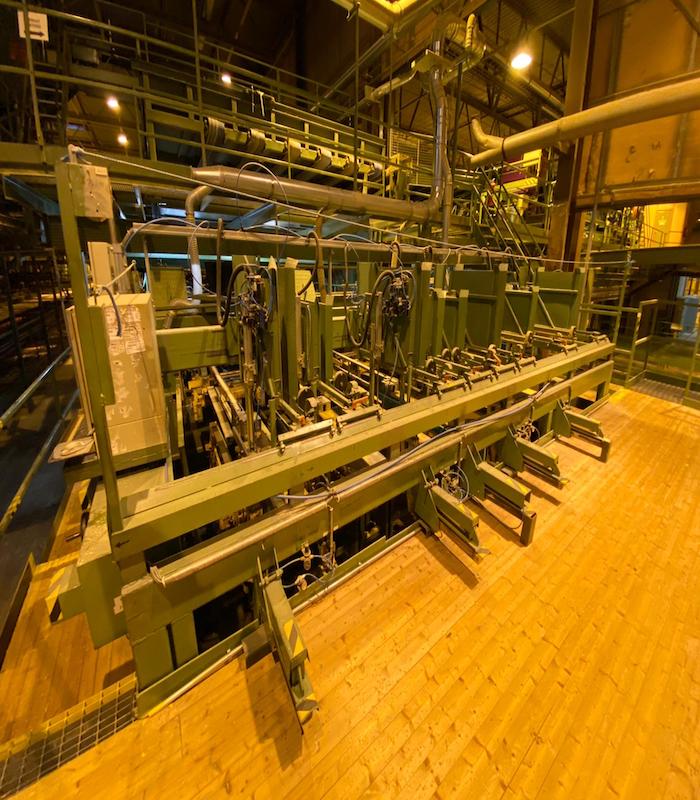

Almab horizontal dry board sorting line

Almab horizontal dry board sorting line after planing with 6 sorting pockets.

- Manufacturer: Almab;

- Year of manufacture: 2003;

- Sorting pockets: 6 horizontal pockets;

- Speed: 15 layers per minute;

- OptiGrader Edger – value optimizing system for board edge processing equipment;

- Supply conveyors;

- Separator;

- Turbo separator;

- End milling machines left and right;

- Supply chain conveyor;

- Measuring scanner;

- Roller conveyors;

- Board feeder for pockets;

- Output by pockets;

- One piece feeder;

- Tri-saw trimming device;

- Forklift with double packing stages;

- Cassettes;

- Output conveyor.

When choosing a sorting line for woodworking: take into account the size and weight of the logs or boards you will be working with; evaluate the speed at which logs or boards need to be processed; required level of automation, sorting line costs and maintenance requirements; the type of wood you will work with and its unique properties; the space required for the sorting line.

Choosing used board and log sorting lines for woodworking can be a cost-effective solution compared to buying new equipment. Additionally, used equipment may have already been tested and proven to be reliable, which can provide reassurance. However, it is important to thoroughly inspect the equipment and make sure it is in good condition before purchasing. Contact us to get the best equipment!